Adult

Baby Diaper manufacturing machine 450PPM Product Description Machine main parameters:

-

| Design speed | 450pieces/min |

-

| Working speed | 350-400 pieces/min |

-

| Qualified rate | 97% (calculate based on 7.5 hours, the rate between qualified products and total production quantity, except substandard products caused by glue applicator error) |

-

| Production efficiency | ≥85% ( calculate based on 7.5 hours, the rate between real production quantity and theory production quantity) |

-

| Capacity | 270KW |

-

| Power | Three phases four wires 380V/50Hz (3×95mm2+1×35 mm2+1×16 mm2) |

-

| Lowest pressure | 6kg/cm³ |

-

| Air compressor | ≥0.8Mpa 1.8m³/min |

-

| Total weight | About 42 tons |

-

| Machine size | 26.5×6×4.5 M (L×W×H) |

-

| Working space | 32×10×6 M (L×W×H) |

-

| Machine color | Metal beach yellow+ sky blue can be changed by order |

-

| Product size | S,M,L,XL (according to order) |

-

| Operation direction | Can be customized (Facing the frontal of the machine) |

-

| Containers | 4X40HQ+1X20FT |

Typical advantages of mechanical parts and Electrical parts: Mechanical Parts: Driving system Adopt several servo motors+ frequency converter+ 3 shafts driving for transmission controlling, main raw materials unwinding driven by frequency control, to guarantee the precision and stability of the machine in high speed, and can realize not change any transmission parts to change the product’s size, can directly set on PLC, easy to operate and maintain All cutter racks adopt with CNC processing, guarantee the precision of bade and prolong the cutter’s lifetime Cutter adopts universal joint coupler transmission Stressed timing belt is widen 32. Wind and Air supply: Vacuum, drum former, dust and wastage collection during production process adopt with several sets air pump and positive pressure blower Air supply is set on the top of machine, made by steel tube, reduce the static electricity, high pressure blower unified air supply, pressure can be adjusted Air tube is set on the top of machine, unified conveyed by galvanized pipe/PVC pipe, connect necessary distributing pipe at the nearest place, neatly arrangement Electrical parts advantages: Electrical parts characteristics: Detection system: Raw materials connection joint auto detection, auto rejection Raw materials breaking auto alarm and auto stop Lycra breaking and missing auto detection and auto rejection Detection switch shelf is convenient to adjust Transmission control Single button start in order, reduce electricity lash Machine can’t start when blower and glue applicator is off, and this function can be shielded for idling test Unwinding and splicing Hydrophobic NW, hydrophilic NW, upper tissue paper, bottom tissue paper,

ADL, and bottom film adopt frequency converter A/B individual unwinding with auto splicing function. Material dia.: bottom filmφ600mm, all the othersφ800mm. Core inner dia. 3 inches. Unwinding is stable when splicing. Splicing can be automatic or by manual. Splicing speed can be set on screen. Splicing dia. can be precisely adjusted to save the material cost Material supplying control unit It adopts Frequency converter to control wood pulp supplying amount. The supplying amount can be set on the touchable screen SAP supplying adopts servo motor control, uninterrupted supplying. The supplying amount can be adjusted and shown on the touchable screen. Shortage alarm Tension of Lycra controlled by servo motor, it can set on touchable screen. Human machine interface Operating screen is set in the middle of machine, with both Chinese and English version Raw material missing, connector, splicing, blower, vacuum pump tripping can be shown with letters on screen Waste product output position, quantity and related parameters can be adjusted on screen Production speed (pieces/min), single shift output, monthly output, annually output, output quantity, accumulative quantity and qualified rate can all be shown on screen Heating system Twist temperature control sensed by thermocouple and temperature controller Heating elements adopt with high quality heating furnace Power leading-in and temperature signal take-out are finished by conductivity Heating system adopt with cylinder compression, when machine is stopped, all heating devices automatically pulled-up, and will automatically reset when machine is stared, and can be switched to manually control Safety device Adopt with safety rack Urgent stop buttons are reasonably set Adopt with several speed up/down, alarm button and device, meanwhile adopt with automatically speed up function, easily operated Adopt with safety board device at entrance of cutter Adopt with lights in front of and at the back side of machine Independent wire casing is set at the side of back transmission box, divided into strong and weak lines, neatly arrangement, with independent door Spray, scraping glue control system Reasonable glue spray position reservation, glue tube goes through from the hole on the top of machine into back transmission cabinet, then straightly comes out from machine board, glue tube can be fixed in transmission cabinet to avoid friction with other parts Matched with glue applicators, spraying automatically, when the machine stops, it stops automatically, also can be manually controlled Adopt glue spray quantity manually tested function on touchable screen when machine stops All glue break station unified controlled by system Supply 0-10V DC tracking signal of glue applicators Adopt with lights at glue spayed position Bridge type glue applicator assembly device Note: Glue applicators are excluded in main machine and can be bought by clients or from us directly. MachineDetail image

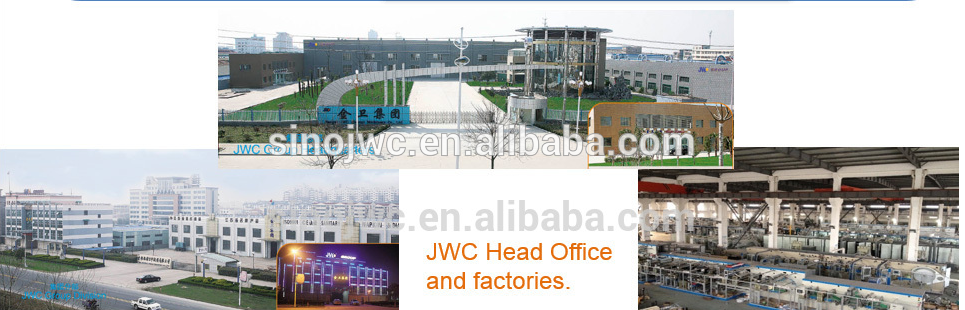

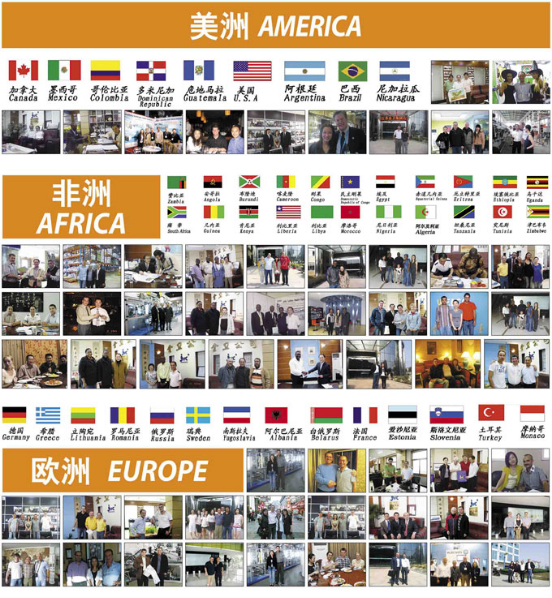

Company Information ♦Since 1996 ♦Specialize in researching &developing hygiene products manufacturing, raw materials importing and exporting, hygienic products manufacturing and real estate development ♦Pass ISO9001 and CE and wins more than 100 national patents as "China Famous Brand" ♦Provide OEM service and different grades of raw materials to overseas customers ♦Export to more than 94 countries in Europe, southeast Asia, south America, Africa and middle east countries.

♦Machine is designed according to customer requirements

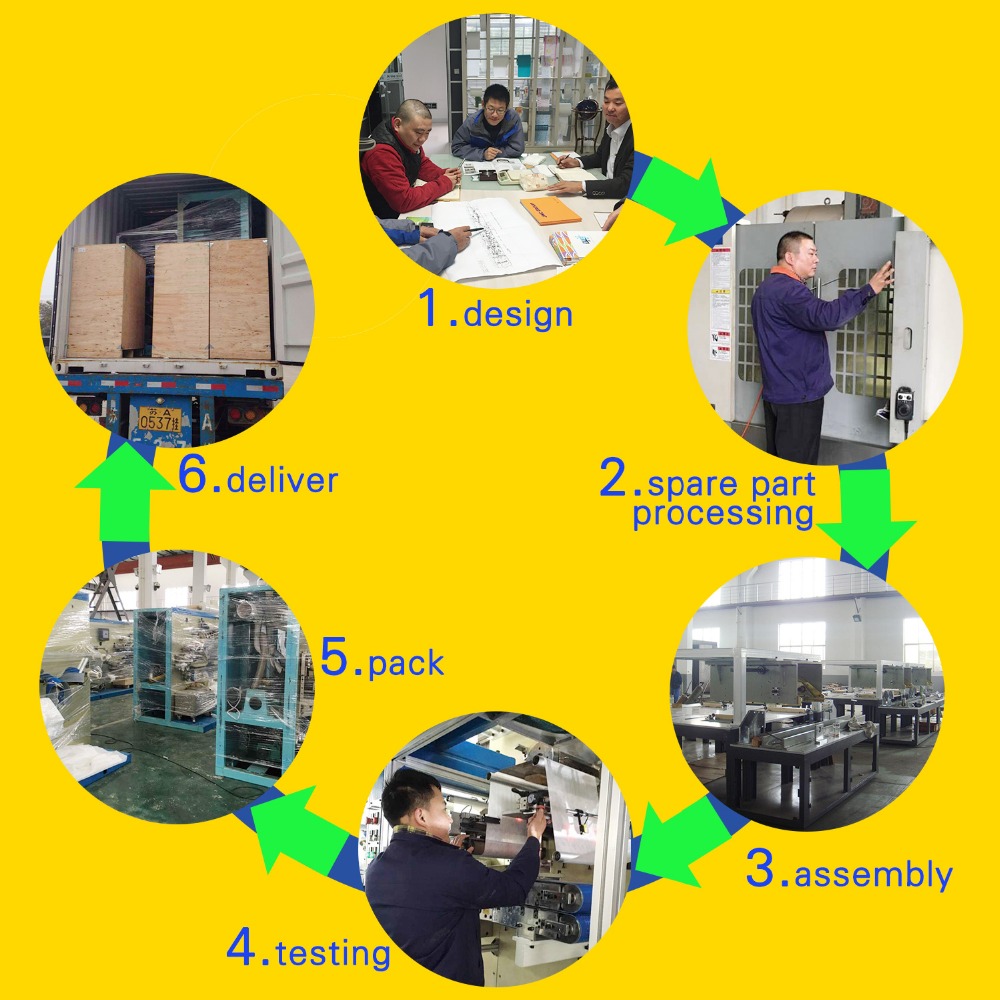

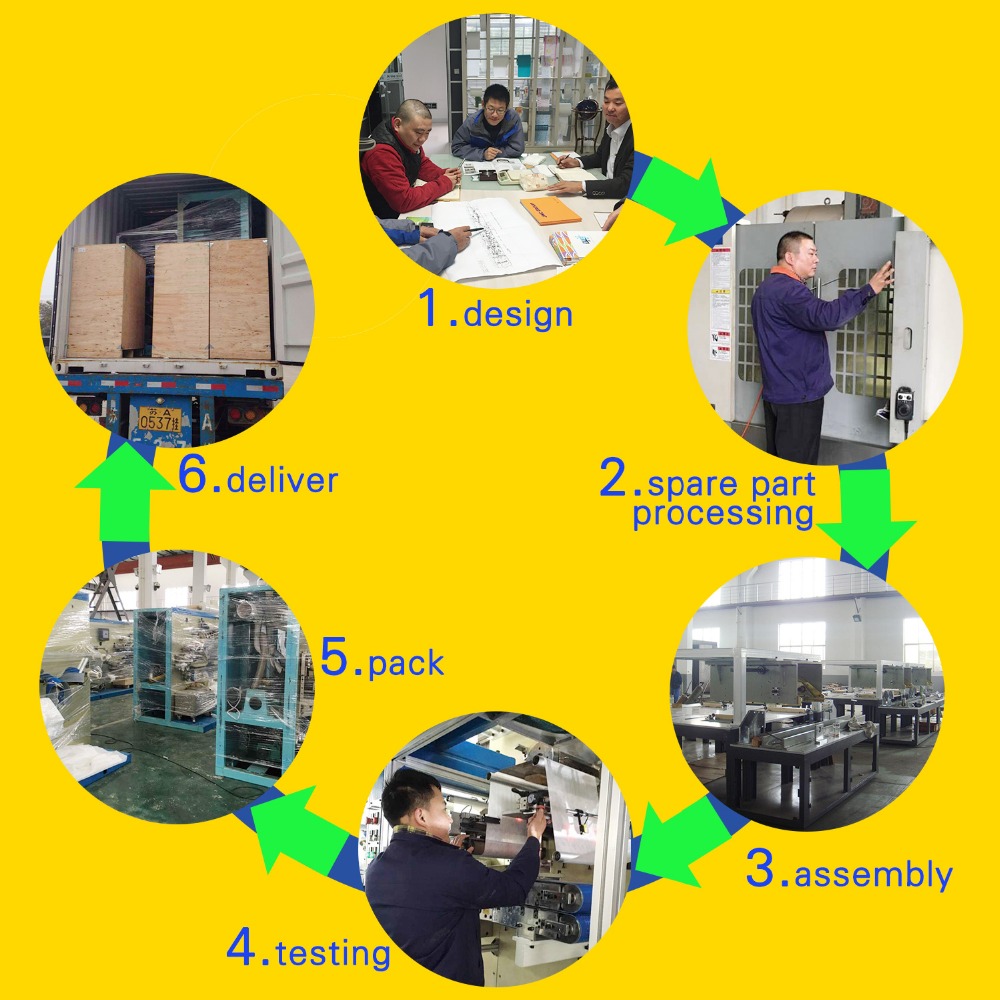

Packing & Delivery

Our Services Pre-Sales Service * Inquiry and consulting support. *Reference materials production cost *Reference workshop layout * Sample testing support. * View our Factory. After-Sales Service * Training how to instal the machine, training how to use the machine in JWC company and in customers' factory. * Engineers available to service machinery overseas. *18 months guarantee * Remote controlling, while customers meet trouble, we could help customers slove problems in China.

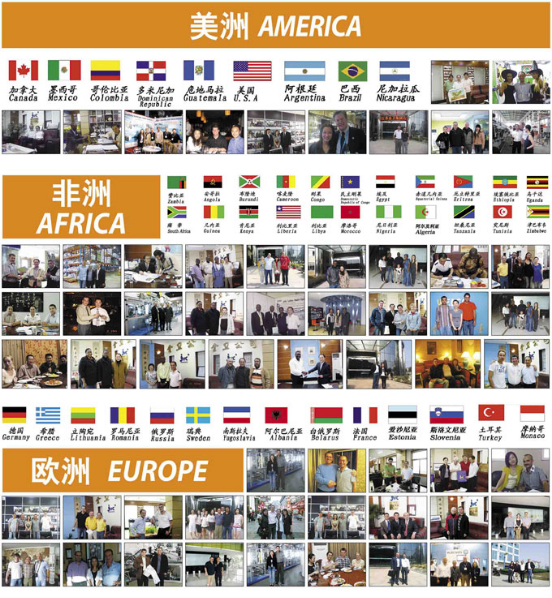

Our customers

FAQ Q1:When can I get the price? A1:We usually quote within 24 hours after we get your inquiry. If you are in urgent to get the price, please call us by 8613655237667 or tell us by Email so that we will take your inquiry as the first priority. Q2:How can I get a sample to check your quality? A2:After price confirmation, we sincerely invite you to our factory to check our operation and production. Q3:Can you do the machines' appearance design for us? A3:Yes. We have a professional team with rich experience in machine's appearance design and manufacturing. Machine structure design is according to the products that you want to produce. Q4:What's your after sales service? A4:When machine is delivered from our factory, we’ll apply the visa for our engineers to your country. As soon as the machine arrives in your factory, we’ll assign them to go immediately. You can also assign your staff to our factory to learn. Q5:Could you also supply raw materials? A5:Yes, surely we can. We have long term cooperation with many raw materials suppliers. They can provide us good quality and good price. This is in our service chain. Q6: If I need to change certain spare parts, how can I confirm the item No. with you? A6: Each spare part on our machine has unique code No. We have the spare parts codes regulation system. We only need you to tell us the laser code No. on the spare part. Then we can confirm with you the drawing at the soonest time and supply you the spare part accordingly.

Contact us if you need more details on

Baby Diaper Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Baby Diaper Manufacturing Machine、

Adult Diaper Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Adult Diaper Machine

Company Information ♦Since 1996 ♦Specialize in researching &developing hygiene products manufacturing, raw materials importing and exporting, hygienic products manufacturing and real estate development ♦Pass ISO9001 and CE and wins more than 100 national patents as "China Famous Brand" ♦Provide OEM service and different grades of raw materials to overseas customers ♦Export to more than 94 countries in Europe, southeast Asia, south America, Africa and middle east countries.

Company Information ♦Since 1996 ♦Specialize in researching &developing hygiene products manufacturing, raw materials importing and exporting, hygienic products manufacturing and real estate development ♦Pass ISO9001 and CE and wins more than 100 national patents as "China Famous Brand" ♦Provide OEM service and different grades of raw materials to overseas customers ♦Export to more than 94 countries in Europe, southeast Asia, south America, Africa and middle east countries.

Packing & Delivery

Packing & Delivery  Our Services Pre-Sales Service * Inquiry and consulting support. *Reference materials production cost *Reference workshop layout * Sample testing support. * View our Factory. After-Sales Service * Training how to instal the machine, training how to use the machine in JWC company and in customers' factory. * Engineers available to service machinery overseas. *18 months guarantee * Remote controlling, while customers meet trouble, we could help customers slove problems in China.

Our Services Pre-Sales Service * Inquiry and consulting support. *Reference materials production cost *Reference workshop layout * Sample testing support. * View our Factory. After-Sales Service * Training how to instal the machine, training how to use the machine in JWC company and in customers' factory. * Engineers available to service machinery overseas. *18 months guarantee * Remote controlling, while customers meet trouble, we could help customers slove problems in China.

Our customers

Our customers

FAQ Q1:When can I get the price? A1:We usually quote within 24 hours after we get your inquiry. If you are in urgent to get the price, please call us by 8613655237667 or tell us by Email so that we will take your inquiry as the first priority. Q2:How can I get a sample to check your quality? A2:After price confirmation, we sincerely invite you to our factory to check our operation and production. Q3:Can you do the machines' appearance design for us? A3:Yes. We have a professional team with rich experience in machine's appearance design and manufacturing. Machine structure design is according to the products that you want to produce. Q4:What's your after sales service? A4:When machine is delivered from our factory, we’ll apply the visa for our engineers to your country. As soon as the machine arrives in your factory, we’ll assign them to go immediately. You can also assign your staff to our factory to learn. Q5:Could you also supply raw materials? A5:Yes, surely we can. We have long term cooperation with many raw materials suppliers. They can provide us good quality and good price. This is in our service chain. Q6: If I need to change certain spare parts, how can I confirm the item No. with you? A6: Each spare part on our machine has unique code No. We have the spare parts codes regulation system. We only need you to tell us the laser code No. on the spare part. Then we can confirm with you the drawing at the soonest time and supply you the spare part accordingly. Contact us if you need more details on Baby Diaper Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Baby Diaper Manufacturing Machine、Adult Diaper Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

FAQ Q1:When can I get the price? A1:We usually quote within 24 hours after we get your inquiry. If you are in urgent to get the price, please call us by 8613655237667 or tell us by Email so that we will take your inquiry as the first priority. Q2:How can I get a sample to check your quality? A2:After price confirmation, we sincerely invite you to our factory to check our operation and production. Q3:Can you do the machines' appearance design for us? A3:Yes. We have a professional team with rich experience in machine's appearance design and manufacturing. Machine structure design is according to the products that you want to produce. Q4:What's your after sales service? A4:When machine is delivered from our factory, we’ll apply the visa for our engineers to your country. As soon as the machine arrives in your factory, we’ll assign them to go immediately. You can also assign your staff to our factory to learn. Q5:Could you also supply raw materials? A5:Yes, surely we can. We have long term cooperation with many raw materials suppliers. They can provide us good quality and good price. This is in our service chain. Q6: If I need to change certain spare parts, how can I confirm the item No. with you? A6: Each spare part on our machine has unique code No. We have the spare parts codes regulation system. We only need you to tell us the laser code No. on the spare part. Then we can confirm with you the drawing at the soonest time and supply you the spare part accordingly. Contact us if you need more details on Baby Diaper Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Baby Diaper Manufacturing Machine、Adult Diaper Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.